Ferrari’s recent unveiling of radical oblong‑piston technology marks one of the most unexpected and potentially transformative developments in internal combustion engine (ICE) design in decades. Engineers at the iconic Italian marque are challenging one of the oldest assumptions in engine architecture — that pistons must be perfectly round — with a new elongated, racetrack‑style shape that they believe could reshape engine performance far beyond what current models achieve.

A Breakthrough in a Century‑Old Design

For over a hundred years, pistons — the heart of every internal combustion engine — have been circular. This shape wasn’t chosen because it is inherently ideal; it was practical, easy to machine, and aligned with manufacturing capabilities of the early 20th century. Ferrari’s engineers, however, saw room for improvement. The result is a new oblong or “stadium‑shaped” piston that deviates from conventional geometry in ways that could fundamentally reshape how engines produce power and efficiency.

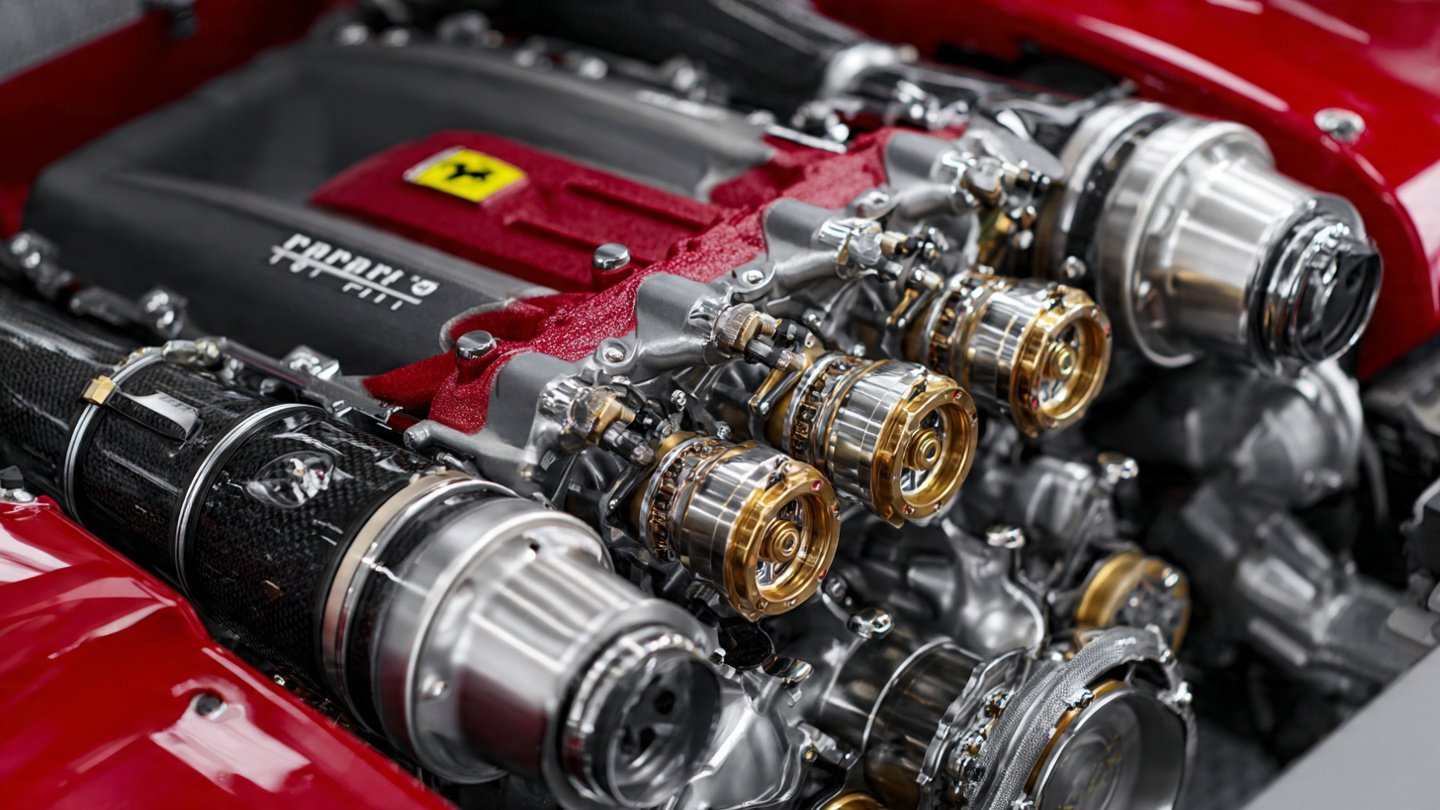

The oblong piston looks almost alien beside a traditional circular counterpart: a rounded rectangle that resembles a race track more than a circle. But this shape isn’t a gimmick — it’s the product of years of simulation, advanced modeling, and a re‑examination of how pressure, friction, and motion within the combustion chamber interact.

Why Change the Piston Shape?

At its core, the piston converts the explosive force of burning fuel into mechanical motion. The circular design has worked for generations, but it also brings inefficiencies. By stretching the piston into an oblong form:

- Combustion area increases without increasing engine height, allowing more fuel‑air mixture to burn more completely and consistently.

- Pressure distribution changes, potentially reducing heat concentration and uncontrolled friction.

- Engine breathing improves, giving engineers new ways to optimize airflow and fuel vaporization.

Equally important, modern machining techniques, advanced coatings, and AI‑assisted design make such complex geometries feasible in ways they weren’t when pistons were first invented. Ferrari’s team didn’t just sketch a new part — they redesigned how they think about the combustion process from the ground up.

The Engineering Behind the Innovation

Ferrari’s approach started not with a shape, but with a question: What kind of pressure map do we want inside the cylinder? From there, engineers used computational models and machine learning to explore forms that would yield the best performance under given constraints — stress tolerance, thermal behavior, friction, and manufacturability. The oblong form emerged as a “sweet spot,” balancing performance benefits with real‑world practicality.

Key engineering adaptations were required:

- AI‑optimized cooling channels ensure heat is managed across the oblong combustion area.

- New precision machining techniques maintain tight tolerances that would previously be impractical.

- Advanced materials and coatings reduce friction and prolong component life under high rpm and thermal stress.

In many ways, this project isn’t about a single new piston but a platform for future engine innovation — one that might endure long past the first prototype models.

How This Could Change Engine Performance

Ferrari’s engineers have already seen promising results during testing on modified blocks. When compared to traditional circular‑piston engines of similar displacement and fueling, the oblong design produced:

- A broader torque curve, meaning more usable power across the rev range rather than a narrow peak.

- Higher thermal efficiency, potentially reducing wasted fuel and lowering emissions.

- Sharper throttle response, giving drivers a more immediate and engaging feel from the engine.

For drivers and enthusiasts, these changes could translate into engines that feel stronger and more linear in delivery, with fewer compromises between performance and everyday usability. Smaller engines could feel more potent or deliver similar output to larger engines while consuming less fuel — a crucial advantage in an era where regulatory pressures and electrification are pushing ICE designs to their limits.

Beyond Performance: Wider Implications

The implications of oblong pistons aren’t limited to Ferrari’s future supercars. If successful in production engines:

- Smaller displacement engines could deliver performance once reserved for much larger units.

- Hybrid powertrains could be paired with more compact combustion units, reducing weight and packaging challenges.

- Motorcycles, sports cars, and even everyday vehicles might adopt scaled‑down versions of the design.

Ferrari isn’t the first automaker to experiment with non‑circular pistons — Honda famously attempted an oval‑piston design in the 1970s and ’80s for its NR500 motorcycle — but those efforts faced sealing and mechanical reliability challenges and didn’t reach commercial success. Ferrari’s version, with modern tools and materials, represents a more viable evolution of the idea.

Challenges Ahead

Despite the excitement, significant hurdles remain before oblong pistons find their way into production cars:

- Manufacturing complexity and cost: New tooling and machining methods could initially make oblong engines more expensive than traditional units.

- Serviceability and reliability: Service networks and maintenance procedures must adapt to new component geometries that behave differently than round pistons under stress.

- Durability under real‑world conditions: Test beds and dynos are one thing; road miles with varying fuel quality and climate conditions are another. Ferrari’s engineers acknowledge that durability and reliability under real‑world use will be the ultimate test of this technology.

Because of the complexity, early oblong piston engines are most likely to appear first in limited‑edition performance models before — and if — they trickle down to broader applications.

A Future Where Combustion Still Matters

In an era dominated by electric vehicles and hybridization, some might question the value of new internal combustion technology. Yet Ferrari’s oblong piston project underscores that the ICE still has untapped potential — especially when reimagined with cutting‑edge tools and creativity.

Far from being an anachronism, combustion engines could become cleaner, more efficient, and more powerful than ever before. Ferrari’s innovations might not overturn the industry overnight, but they hint at a future where electrification and advanced combustion technologies coexist, offering drivers the best of both worlds.

What It Means for Enthusiasts and the Automotive World

If Ferrari successfully introduces oblong‑piston engines:

- Driving experience could feel more immediate and rewarding, with broader torque delivery and enhanced responsiveness.

- Engine design philosophy might shift industry‑wide, prompting rivals to explore unconventional geometries.

- Hybrid systems could become lighter and more compact without sacrificing performance, improving handling and efficiency.

What Ferrari has done may seem like a small tweak — a shift in shape — but its consequences could be vast. By daring to rethink a fundamental part long taken for granted, Ferrari is positioning itself not just as a maker of dreams, but as a genuine driver of engineering evolution.